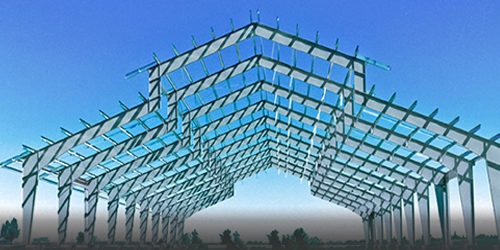

Effective Installment Practices for Steel Structures: Improving Your Building Process

From careful preparation to the utilization of pre-engineered elements, each action plays an essential role in accelerating the building and construction timeline. By diving right into the world of advanced installment methods and guaranteeing rigorous top quality control measures, the possibility for optimizing the entire building procedure becomes not just a possibility however a practical reality.

Preparation for Efficiency

When intending to make best use of effectiveness in steel building installation, thorough preparation is crucial. Proper preparation sets the structure for a smooth and orderly construction process, ultimately conserving time and resources. The preliminary step in preparing for effectiveness is conducting a comprehensive site analysis. This evaluation assists recognize any possible barriers or challenges that may emerge throughout the setup procedure, enabling preemptive solutions to be devised. steel buildings.

In addition, reliable communication among all stakeholders is paramount during the planning phase. Regular meetings and updates help keep everybody on the exact same page, reduce misunderstandings, and cultivate a collective functioning environment - steel buildings. By spending effort and time into thorough planning, steel structure installment can be implemented with accuracy and performance

Utilizing Pre-Engineered Parts

Effective steel building setup methods can be even more enhanced by leveraging the application of pre-engineered elements. Pre-engineered elements are created and made off-site to precise requirements, making sure compatibility and simplicity of assembly throughout the construction procedure. By integrating pre-engineered elements such as beam of lights, columns, trusses, and panels, home builders can streamline the installment procedure, decrease on-site labor requirements, and reduce building and construction waste.

One key advantage of making use of pre-engineered components is the considerable time cost savings they use. Since these components are produced in a regulated setting, they reach the building site prepared for fast and efficient setup. This not only speeds up the general building and construction timeline however additionally assists to minimize job hold-ups and associated prices.

Additionally, pre-engineered elements are engineered for optimal efficiency and structural integrity, making sure the lasting sturdiness and stability of the steel building. By utilizing these standardized elements, home builders can attain constant high quality across different jobs while also gaining from price financial savings linked with decreased product waste and labor expenditures.

Enhancing Building Sequencing

To make best use of efficiency and performance in steel building installation, critical optimization of construction sequencing is critical. By very carefully intending the order in which jobs are executed, building and construction groups can lessen downtime, minimize product handling, and improve the general building procedure.

Executing Advanced Installment Techniques

Implementing sophisticated setup techniques enhances the effectiveness and top quality of steel structure construction jobs. More Help By incorporating advanced methods such as computer-aided design (CAD) for precise preparation, prefabrication of components off-site, and utilization of advanced equipment like robot welders, building and construction groups can substantially streamline the installation process. CAD software program enables for thorough 3D modeling, helping in the visualization of the last structure and guaranteeing accurate element measurements for a perfect fit during assembly. Prefabrication reduces on-site labor demands and building and construction time by fabricating structure aspects in a regulated setting, lessening errors and remodel. Using robotic welders raises the rate and accuracy of welding jobs, enhancing the general architectural integrity of the steel structure. Moreover, applying sophisticated techniques advertises safety by decreasing hands-on labor needs and possible office hazards. By accepting development in installation techniques, construction jobs can be finished quicker, with better outcomes, and within budget restraints.

Guaranteeing Quality Assurance

Building upon the utilization of sophisticated installation browse around here techniques, keeping rigid quality assurance measures is extremely important in making sure the architectural integrity and reliability of steel building projects. Quality assurance begins with the choice of premium products that meet sector standards and specs. Regular inspections throughout the construction procedure assistance identify any type of discrepancies from the style or potential issues that might endanger the structure's toughness.

Documents is an important facet of top quality control, ensuring that all action in the installation procedure follow the authorized plans and laws. This consists of recording evaluations, material qualifications, and any alterations made throughout building and construction. Implementing a clear communication method amongst team members and subcontractors assists simplify the quality control procedure and address any kind of issues quickly.

Conclusion

In verdict, embracing effective installment practices for steel structures is crucial for enhancing the building procedure. It is necessary to focus on effectiveness in order to make best use of performance and attain effective results in steel building construction.

To take full advantage of efficiency and efficiency in steel building installment, calculated optimization of construction sequencing is paramount. Generally, by enhancing construction click resources sequencing, steel structure installment can be completed a lot more successfully, saving time and prices in the process.

Carrying out innovative installment techniques enhances the effectiveness and high quality of steel structure construction projects. By prioritizing top quality control throughout the installation procedure, building and construction teams can supply steel buildings that are not just reliable but dependable and also resilient.

In conclusion, embracing reliable setup methods for steel structures is vital for enhancing the building and construction procedure.